Membongkar Sifat Unik Filem Black PET

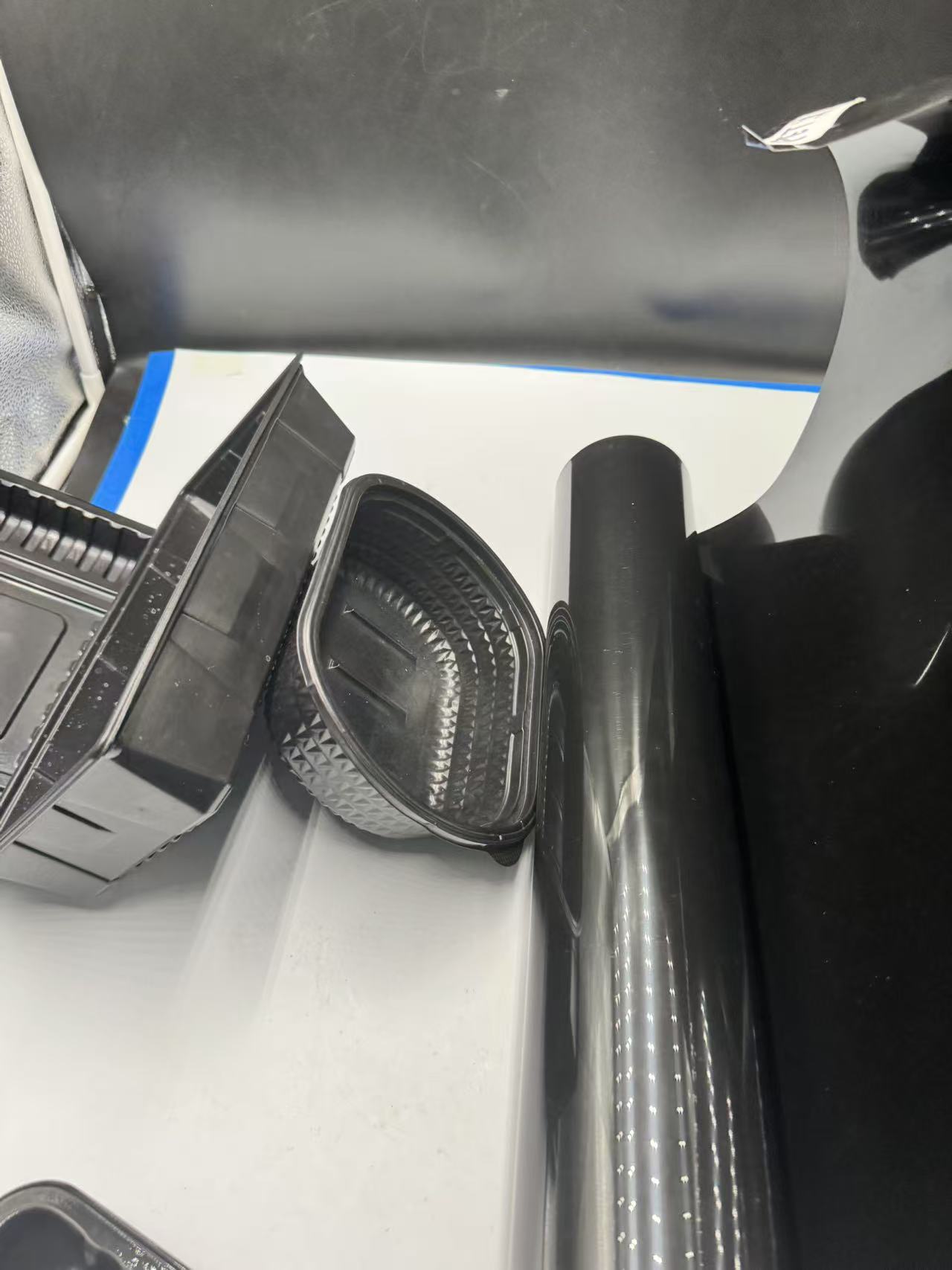

2025-07-16 17:16Polyethylene Terephthalate (PET) film is a highly versatile material widely recognized for its strength, clarity, and recyclability. Among its many variants, black PET film stands out due to its unique aesthetic appeal, functional properties, and adaptability across various industries. This article delves into the characteristics of black PET film and explores its extensive applications, including food blister packaging, disposable tableware, antistatic packaging, meat trays, and fruit trays. With its robust properties and eco-friendly potential, black PET film is becoming an indispensable material in modern manufacturing.Characteristics of Black PET FilmBlack PET film is a specialized form of PET film, typically produced by incorporating black pigments or dyes during the manufacturing process. Its distinct properties make it a preferred choice for applications requiring durability, aesthetics, and functionality. Below are the key characteristics that define black PET film:High Mechanical Strength and Durability

Black PET film exhibits excellent tensile strength and resistance to tearing, making it ideal for applications requiring robust packaging. Its ability to withstand mechanical stress ensures that products remain protected during transportation, handling, and storage. For instance, in food packaging, black PET film maintains structural integrity even under varying temperatures and physical pressures.

Excellent Barrier Properties

Black PET film provides superior barriers against moisture, gases, and light, which is critical for preserving the freshness and shelf life of perishable goods. The black pigmentation enhances its ability to block UV light, protecting light-sensitive products such as meats and certain fruits from degradation caused by exposure to sunlight.

Aesthetic Appeal and Branding Potential

The sleek, professional appearance of black PET film makes it a favorite for premium packaging applications. Its dark, glossy finish conveys sophistication and quality, allowing brands to differentiate their products in competitive markets. For example, black PET film is often used in high-end food packaging to create a luxurious visual appeal that attracts consumers.

Thermal Stability and Thermoforming Capability

Black PET film is highly suitable for thermoforming, a process where the film is heated and molded into specific shapes, such as trays or containers. Its thermal stability allows it to maintain its shape and properties even when exposed to high temperatures during processing or use, making it ideal for blister packaging and disposable tableware.

Antistatic Properties

Certain formulations of black PET film can be engineered to possess antistatic properties, reducing the buildup of static electricity. This is particularly valuable in packaging sensitive electronic components, where static discharge could cause damage. The antistatic feature ensures safe handling and storage of delicate products.

Recyclability and Sustainability

Like other PET-based materials, black PET film is recyclable, aligning with global sustainability goals. Advances in recycling technologies have made it easier to process black PET film, reducing its environmental impact and enabling its use in circular economy models. This eco-friendly aspect appeals to brands and consumers prioritizing sustainable packaging solutions.

Chemical Resistance

Black PET film is resistant to many chemicals, oils, and greases, making it suitable for packaging products that may come into contact with such substances. This property is particularly beneficial in food packaging, where the film must protect contents from contamination while maintaining safety and hygiene standards.

Applications of Black PET FilmThe unique combination of strength, aesthetics, and functionality makes black PET film a go-to material for a wide range of applications. Below, we explore its use in food blister packaging, disposable tableware, antistatic packaging, meat trays, and fruit trays, highlighting how its properties cater to the specific needs of each application.

1. Food Blister PackagingBlister packaging is widely used in the food industry to encase products securely while providing visibility and protection.

Black PET film is increasingly popular in this application due to its ability to combine functionality with visual appeal. For example, pre-packaged snacks, confectionery, and ready-to-eat meals often use black PET film for its UV-blocking properties, which help preserve product freshness by shielding contents from light-induced spoilage.The thermoforming capability of black PET film allows manufacturers to create custom-shaped blister packs that securely hold food items in place. Its high clarity (even in black) ensures that the packaging remains visually appealing, while its durability prevents damage during transport. Additionally, black PET film’s chemical resistance ensures that it remains unaffected by oils or sauces, maintaining food safety and quality.For instance,

in the packaging of premium chocolates or gourmet snacks, black PET film provides a sleek, high-end look that enhances brand perception. The film’s ability to form rigid, protective structures also ensures that delicate items, such as pastries or fragile snacks, remain intact from production to consumption.

2. Disposable Tableware PackagingDisposable tableware, such as plates, bowls, and cutlery, has seen a surge in demand due to the rise of takeout and delivery services. Black PET film is widely used to manufacture these items, thanks to its lightweight nature, durability, and aesthetic appeal. The film’s thermal stability allows it to withstand hot and cold foods without warping or degrading, making it suitable for a variety of dining scenarios.In restaurants and catering services, black PET film-based tableware is favored for its modern, elegant appearance. For example, black PET trays used for sushi or appetizers create a striking contrast with colorful food items, enhancing the visual presentation. The film’s recyclability also aligns with the growing demand for sustainable disposable options, as consumers and businesses seek eco-friendly alternatives to traditional single-use plastics.Moreover, black PET film’s resistance to grease and moisture ensures that it can handle oily or saucy foods without compromising its structural integrity. This makes it an excellent choice for packaging takeout meals, where durability and leak-proof properties are essential.

3. Antistatic PackagingIn industries such as electronics and telecommunications, static electricity poses a significant risk to sensitive components. Black PET film can be treated with antistatic additives to prevent the buildup of static charge, making it an ideal material for packaging items like circuit boards, microchips, and other electronic components.The antistatic properties of black PET film ensure that delicate electronics are protected from electrostatic discharge (ESD), which can cause irreparable damage. The film’s durability and flexibility also allow it to be molded into trays or inserts that securely hold components during shipping and storage. For example, black PET film is used in the production of ESD-safe trays for semiconductor devices, ensuring safe handling throughout the supply chain.The aesthetic appeal of black PET film also plays a role in this application, as it provides a professional, high-tech look that aligns with the branding of electronic products. Its recyclability further enhances its appeal, as manufacturers seek sustainable solutions for packaging electronic goods.

4. Meat TraysIn the meat packaging industry, black PET film is widely used to create trays that combine functionality with visual appeal. Meat trays made from black PET film offer excellent barrier properties, preventing oxygen and moisture from compromising the quality of fresh or processed meats. The film’s UV-blocking capabilities also help extend shelf life by protecting meat from light-induced oxidation, which can cause discoloration and spoilage.The thermoforming process allows black PET film to be shaped into rigid, leak-proof trays that securely hold meats and prevent juices from spilling. This is particularly important for retail displays, where presentation and hygiene are critical. For example, black PET meat trays are commonly used in supermarkets to package cuts of beef, pork, or poultry, offering a premium look that enhances the perceived value of the product.Additionally, black PET film’s recyclability makes it a sustainable choice for meat packaging, as it can be collected and processed through existing PET recycling streams. This aligns with consumer preferences for environmentally responsible packaging solutions.

5. Fruit TraysBlack PET film is also used in the production of fruit trays, particularly for premium or delicate fruits such as berries, grapes, or stone fruits. The film’s strength and rigidity ensure that trays can support the weight of the fruit without collapsing, while its barrier properties protect against moisture loss and contamination.The black color of the film enhances the visual appeal of colorful fruits, creating a striking contrast that draws consumer attention in retail settings. For example, black PET trays used for packaging strawberries or cherries make the vibrant red hues pop, improving the product’s marketability. The film’s ability to be thermoformed into custom shapes also allows for trays that securely hold fruits in place, reducing damage during transport.Moreover, black PET film’s recyclability and lightweight nature make it an eco-friendly choice for fruit packaging.