Meneroka Kepelbagaian Filem PP dalam Pembungkusan Lepuh Pinggan Makan Pakai

2025-02-28 15:37Introduction: Unveiling the Power of PP Film

In the realm of modern packaging, few materials have demonstrated the adaptability and reliability of polypropylene (PP) film, often referred to as PPfilm in technical contexts.  This versatile thermoplastic has carved a niche for itself across industries, but its application in disposable tableware blister packaging stands out as a testament to its unique properties. Imagine a bustling food festival: vendors serve steaming hot meals in lightweight, sturdy containers that resist cracking under pressure, maintain hygiene, and—crucially—offer a sustainable edge over traditional alternatives. This is where PPfilm shines, blending practicality with innovation to meet the demands of today’s fast-paced, eco-conscious world.

This versatile thermoplastic has carved a niche for itself across industries, but its application in disposable tableware blister packaging stands out as a testament to its unique properties. Imagine a bustling food festival: vendors serve steaming hot meals in lightweight, sturdy containers that resist cracking under pressure, maintain hygiene, and—crucially—offer a sustainable edge over traditional alternatives. This is where PPfilm shines, blending practicality with innovation to meet the demands of today’s fast-paced, eco-conscious world.

Polypropylene, a polymer derived from propylene monomers, is celebrated for its clarity, strength, and thermal resilience. In blister packaging for disposable tableware—think trays, plates, and cutlery holders—PPfilm offers a compelling combination of form and function. This article delves into the characteristics of PPfilm, explores its specific uses in blister packaging for disposable tableware, and evaluates its advantages and challenges, all while painting a vivid picture of its real-world impact.

Section 1: Understanding the Core Characteristics of PP***Film

1.1 Physical Properties: Clarity, Flexibility, and Strength

PPfilm is a standout material due to its impressive physical attributes. It boasts a high gloss and transparency, making it visually appealing for packaging applications where product visibility matters. Picture a stack of disposable trays at a supermarket deli counter: the crystal-clear PPfilm allows customers to inspect the contents—whether it’s a fresh salad or a pre-cooked meal—enhancing trust and appeal.

Beyond aesthetics, PP***film offers remarkable tensile strength and flexibility. Unlike brittle materials, it can withstand bending and stretching without tearing, a critical feature for blister packaging that must endure handling and transport. Its semi-crystalline structure contributes to this toughness, providing a balance between rigidity and elasticity that ensures tableware remains securely encased until use.

1.2 Thermal Resilience: A High Melting Point Advantage

One of PPfilm’s defining traits is its elevated melting point, typically around 160–170°C (320–338°F), significantly higher than polyethylene (PE). This makes it ideal for applications involving heat, such as microwaveable disposable tableware. Imagine reheating a meal in a PPfilm-packaged tray: the material resists warping or melting, preserving both structural integrity and food safety. This thermal stability also suits it for high-temperature sterilization processes, ensuring hygiene in food service settings.

1.3 Chemical Resistance and Safety

PP***film excels in resisting a wide range of chemicals, including acids, bases, and solvents. This property is vital for disposable tableware packaging, where exposure to oily foods, acidic sauces, or cleaning agents is common. It remains inert, preventing leaching of harmful substances into food—a key consideration for consumer safety. Regulatory bodies worldwide approve PP for food contact, reinforcing its reliability in this domain.

1.4 Barrier Properties and Variants

While PPfilm naturally offers moderate moisture and gas barrier properties, advancements like metallization or co-extrusion with other polymers enhance its performance. For instance, a metallized PPfilm can extend the shelf life of packaged tableware by reducing oxygen and water vapor transmission. In blister packaging, this ensures that pre-packaged utensils or trays remain uncontaminated and functional over time.

1.5 Recyclability: A Nod to Sustainability

Sustainability is a buzzword in modern packaging, and PP***film aligns well with this trend. It is fully recyclable, capable of being reprocessed into new products without releasing toxic byproducts during waste management. However, it’s not biodegradable, a limitation offset by its recyclability and durability, which reduce the need for frequent replacement.

Section 2: PP***Film in Blister Packaging for Disposable Tableware

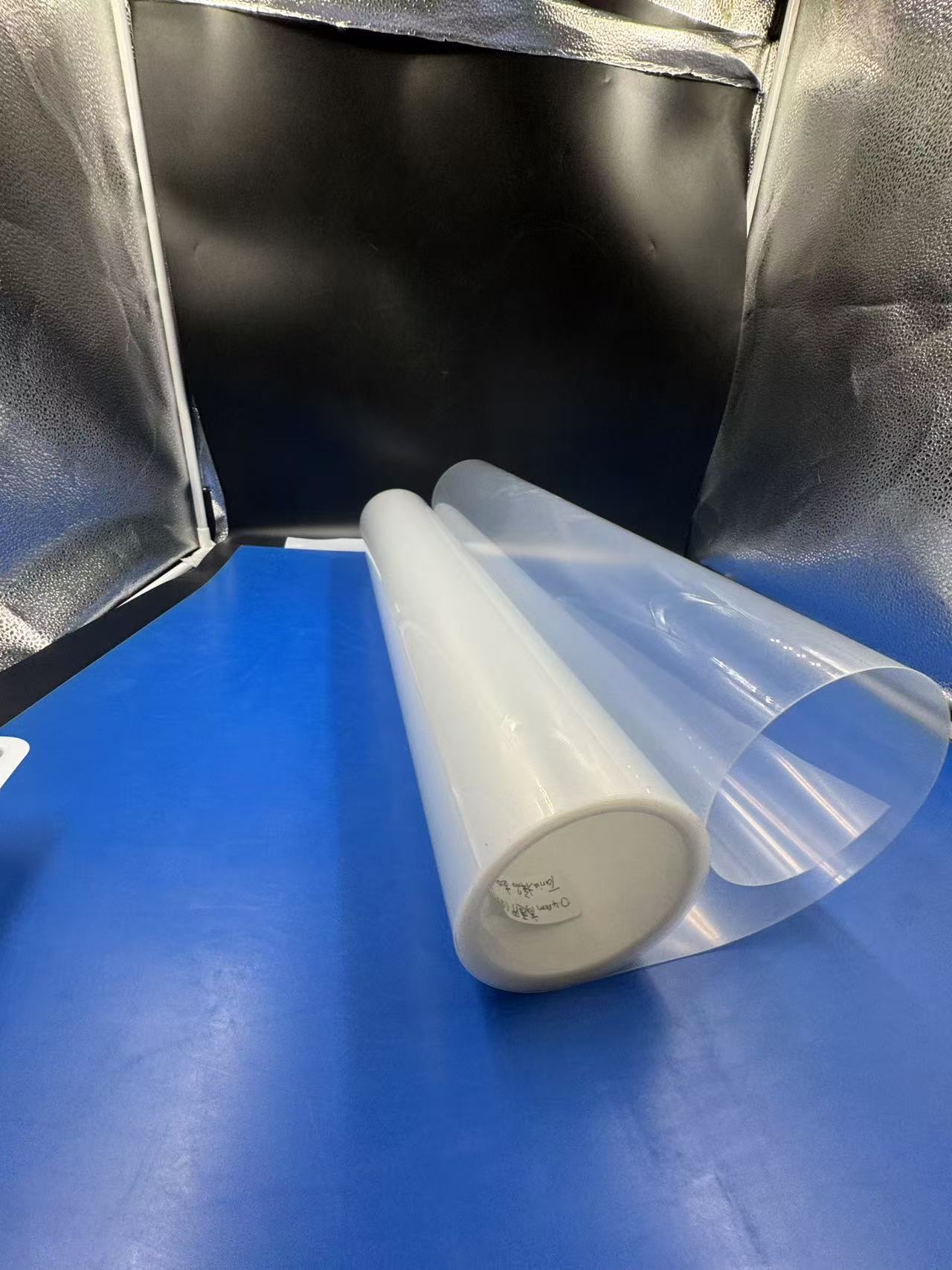

2.1 The Blister Packaging Process: Thermoforming with PP***Film

Blister packaging involves forming cavities or pockets in a plastic film to encase products, typically sealed with a backing material like foil or paperboard. For disposable tableware—such as forks, spoons, or compartmentalized trays—PPfilm is thermoformed into precise shapes using heat and pressure. The process begins with a roll of PPfilm heated to its thermoelastic range (around 130–150°C), then molded over a die to create cavities. Once cooled, these pockets hold the tableware securely, ready for sealing and distribution.

The narrow thermoforming window of PPfilm requires precise temperature control, but modern machinery has overcome this challenge, making it a viable choice. Visualize a production line: rolls of glossy PPfilm unfurl, pass through heating zones, and emerge as perfectly shaped trays in seconds, showcasing the material’s adaptability.

2.2 Specific Applications in Disposable Tableware

Trays and Plates: PP***film forms lightweight, stackable trays for meals on the go—think airline meals or takeout containers. Its heat resistance supports hot food service, while its strength prevents cracking under load.

Cutlery Holders: Disposable forks, knives, and spoons are often packaged in PP***film blisters, ensuring hygiene and ease of dispensing. The film’s clarity lets users see the utensils, enhancing perceived quality.

Multi-Compartment Containers: For meal kits or bento-style servings, PP***film creates segmented trays that keep foods separate, leveraging its chemical resistance to handle diverse ingredients without cross-contamination.

2.3 Real-World Examples

Consider a busy urban food truck: customers grab PPfilm-packaged trays loaded with steaming noodles or grilled meats. The packaging withstands heat, resists grease, and stacks neatly for storage—an unsung hero of convenience. In institutional settings like hospitals or schools, PPfilm blisters encase pre-portioned utensils, ensuring sterility and reducing waste through single-use efficiency.

Section 3: Advantages of PP***Film in Disposable Tableware Blister Packaging

3.1 Durability and Protection

PP***film’s toughness ensures that tableware survives the rigors of shipping and handling. A tray dropping off a conveyor belt won’t shatter its packaging, thanks to the film’s impact resistance—a stark contrast to more fragile alternatives like polystyrene (PS).

3.2 Cost-Effectiveness

Polypropylene is abundant and relatively inexpensive to produce, keeping packaging costs low. For disposable tableware, where margins are tight, this affordability is a game-changer, allowing vendors to prioritize quality without breaking the bank.

3.3 Versatility in Design

The flexibility of PP***film enables intricate blister designs—think deep-drawn pockets for bulky items or shallow ones for flatware. Manufacturers can tailor shapes to specific needs, enhancing both functionality and branding through custom molds.

3.4 Environmental Edge