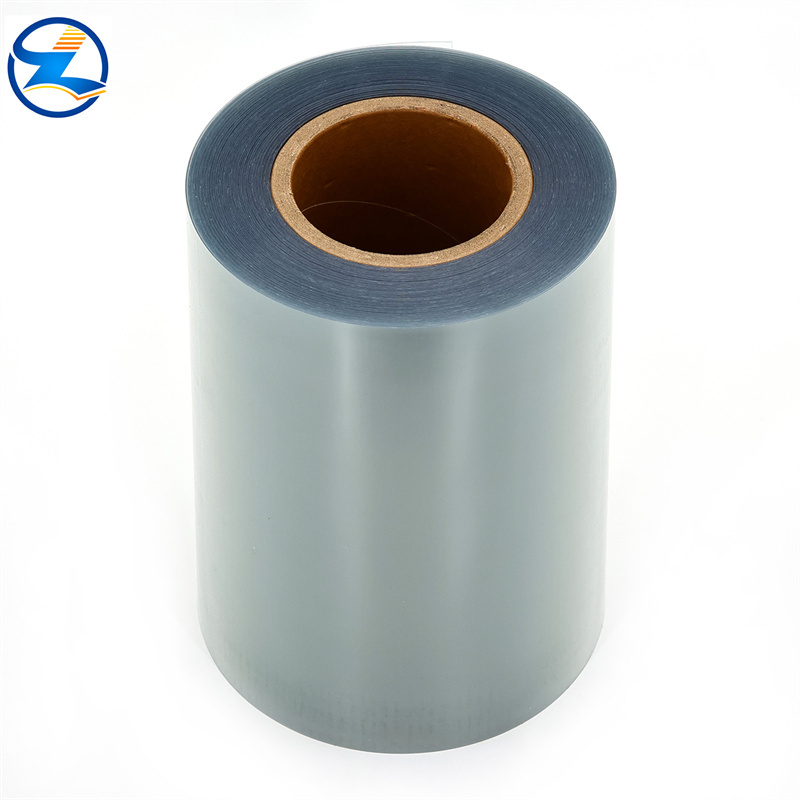

Filem PVC Tegar Gred Farmaseutikal Jelas 0.2mm

Kesihatan yang sihat sentiasa dibungkus dalam makanan dan ubat farmaseutikal yang tidak toksik dan bebas kimia. Untuk pembungkusan terbaik, TOPLEADERPLASTIC mengeluarkan filem PVC tegar yang sangat baik yang memanfaatkan bahan mentah gred farmaseutikal dan proses kalendar terkini. Filem ini dihasilkan di bawah persekitaran terkawal mengikut norma GMP semasa dan mematuhi semua peraturan pembungkusan makanan dan farmasi.

Ciri-ciri Produk:

Dayakan pensterilan sinaran

Pembentukan termo terbaik dalam kelasnya

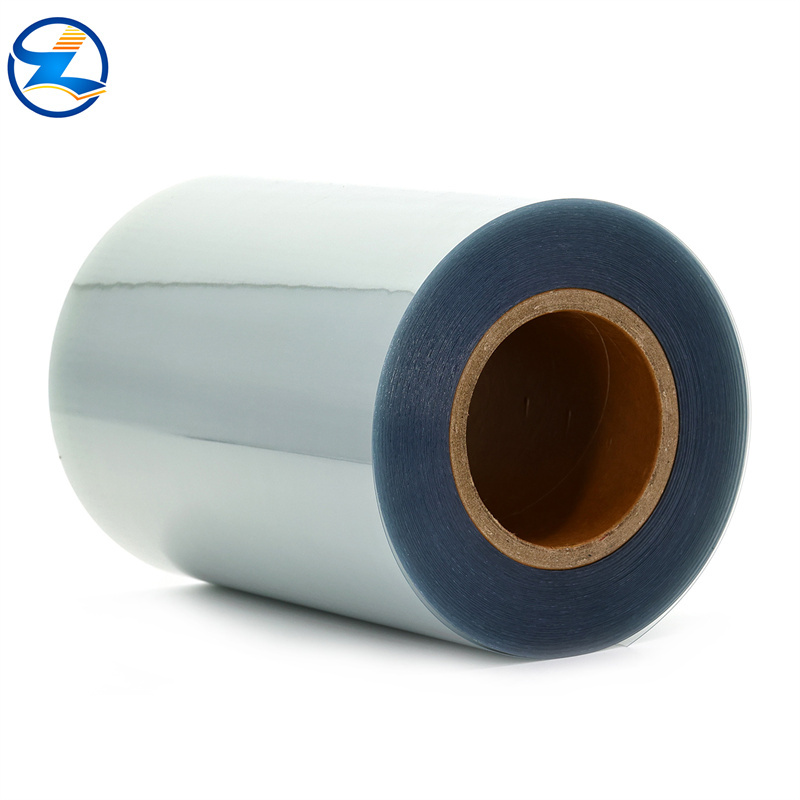

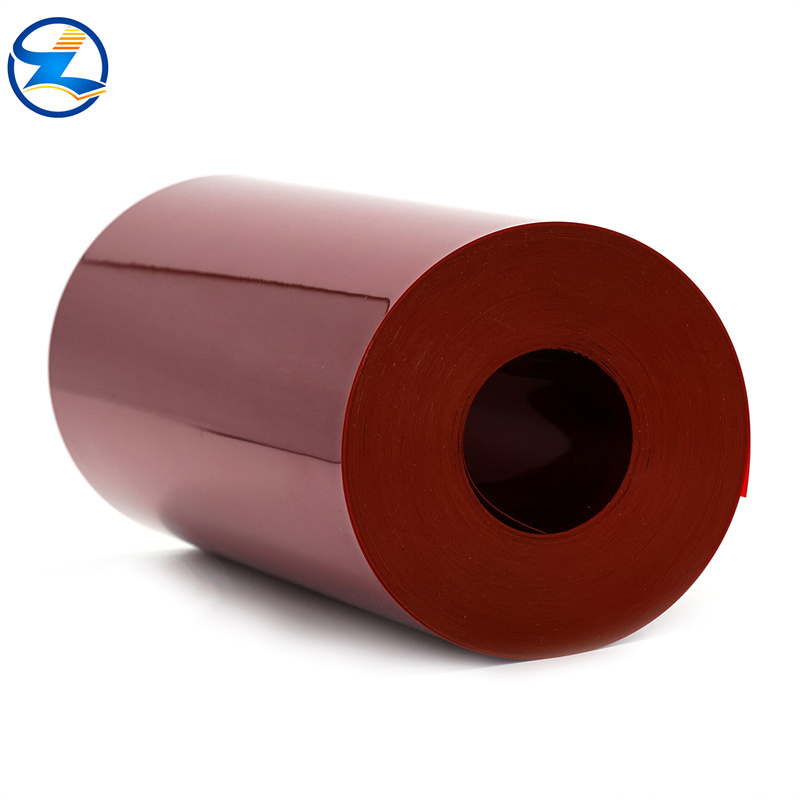

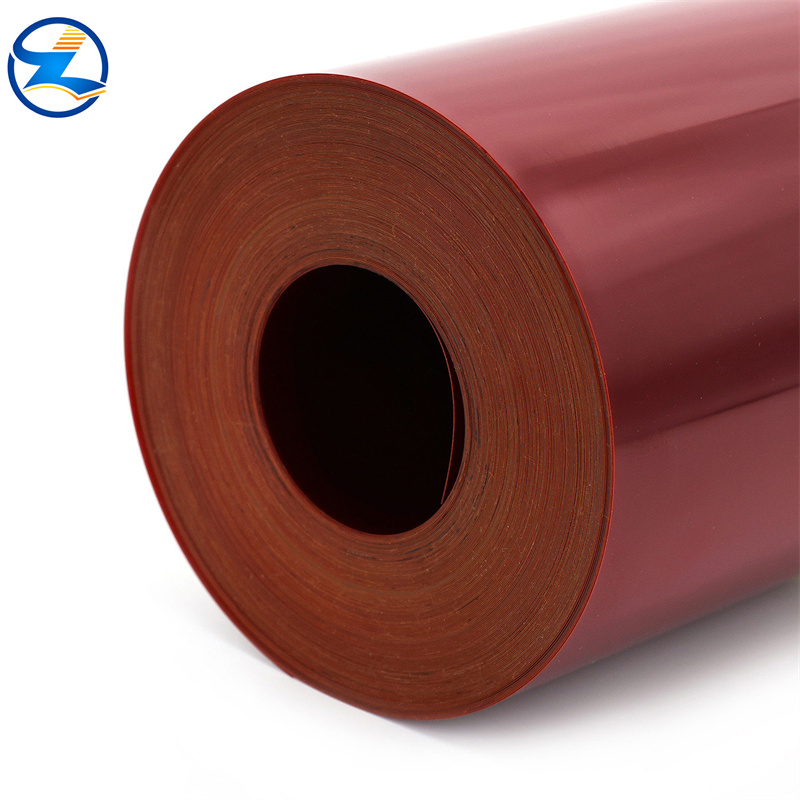

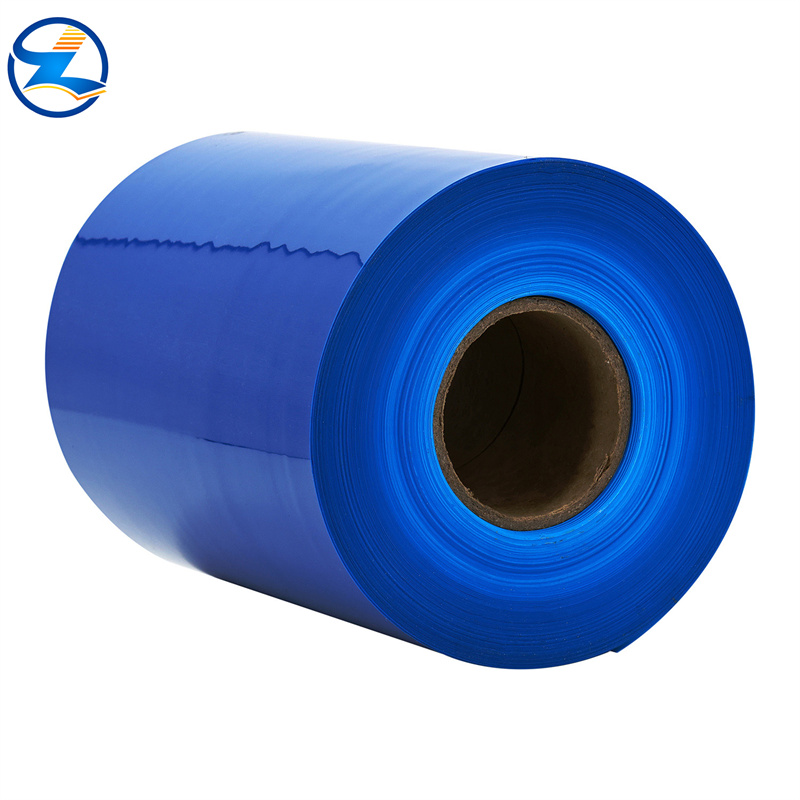

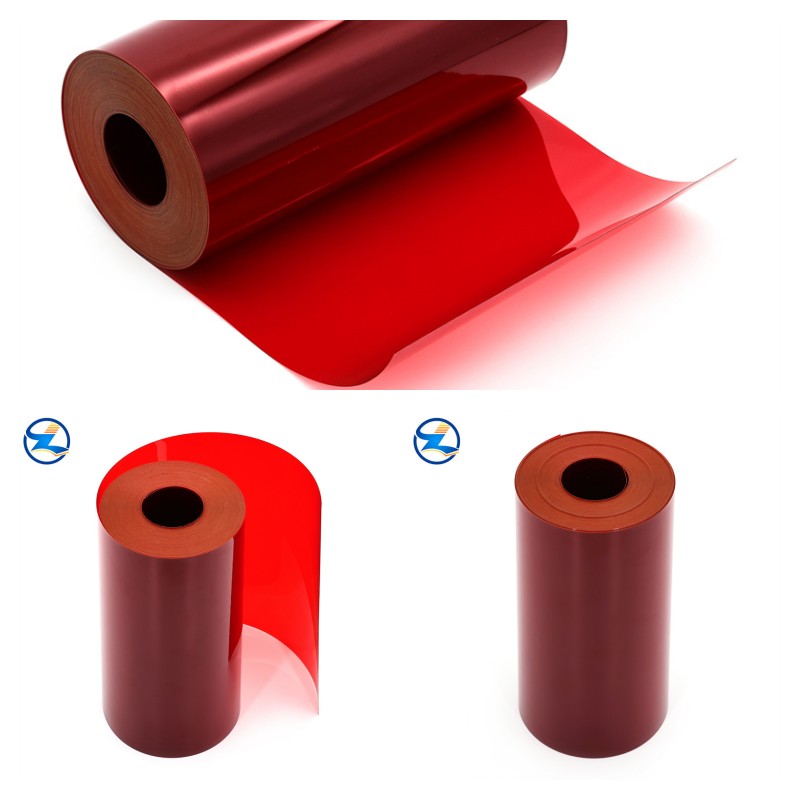

Terdapat dalam pelbagai saiz dan warna warna

Sifat organoleptik terbaik jadi rasa dan bau adalah neutral

Sifat pengedap haba yang luar biasa

Kestabilan dimensi tinggi

Penghantaran gas dan kadar lembapan adalah rendah

Pembentukan vakum yang ketara, keliatan dan ketahanan

Penyelesaian pembungkusan moden oleh TOPLEADERPLASTIC berkisar antara 50 hingga 700 mikron dan memerlukan kurang bahan api dalam pembuatan dan pengangkutan berbanding logam, kaca atau bahan lain. Itu meningkatkan penggunaan dan permintaannya dalam pembungkusan di seluruh dunia.

- Top Leader

- China

- 7 hari

- 500 tan sebulan

- maklumat

- Video

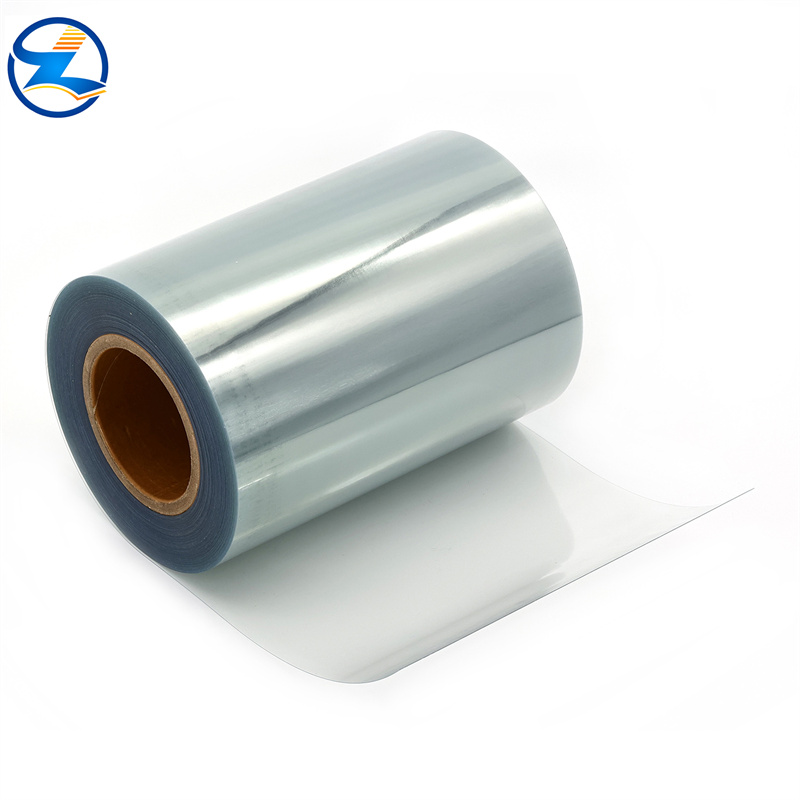

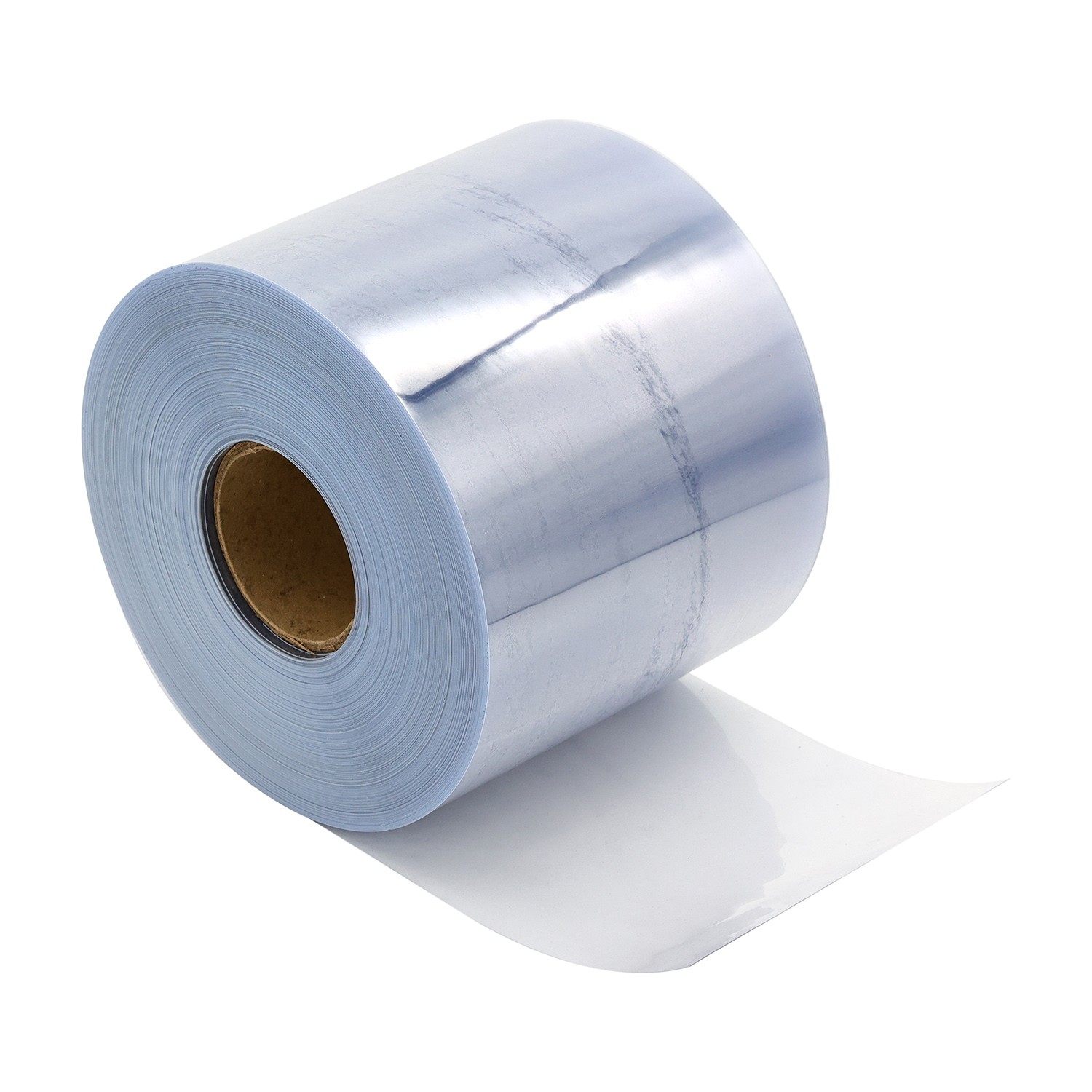

Filem PVC tegar gred farmaseutikal jelas 0.2mm kami direka untuk digunakan dalam pembungkusan produk farmaseutikal. Filem ini diperbuat daripada bahan PVC berkualiti tinggi yang memenuhi piawaian industri yang ketat untuk keselamatan dan ketulenan.

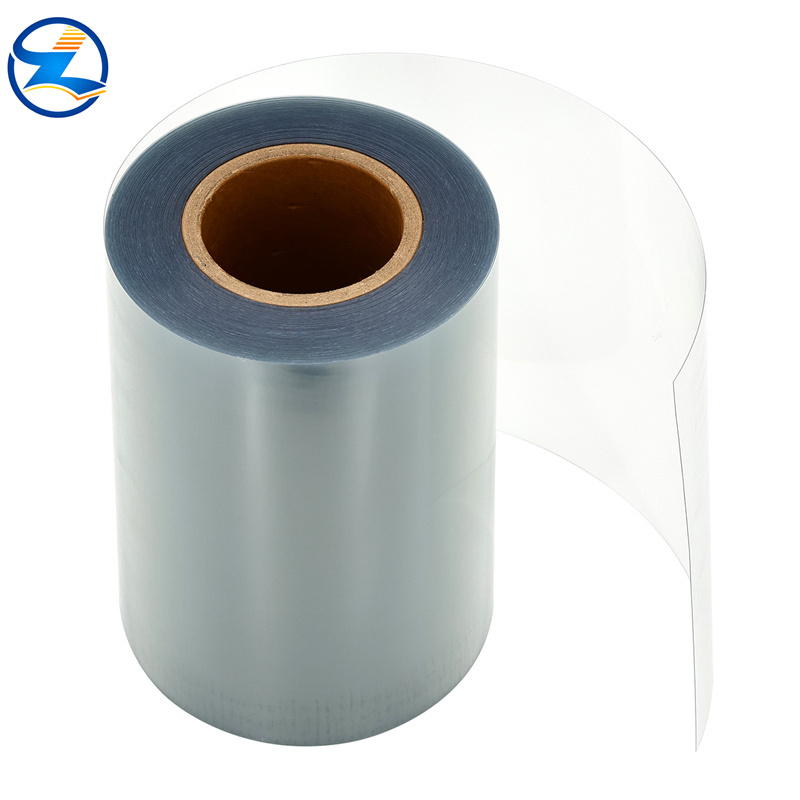

Reka bentuk yang jelas bagi filem ini membolehkan keterlihatan produk yang dibungkus dengan mudah, menjadikannya ideal untuk digunakan dalam pembungkusan farmaseutikal di mana pengenalan produk adalah penting. Ketebalan 0.2mm menyediakan penghalang tahan lama yang melindungi kandungan daripada unsur luaran seperti kelembapan, cahaya dan bahan cemar.

Filem PVC tegar gred farmaseutikal kami sesuai untuk digunakan dengan pelbagai kaedah pembungkusan, termasuk termoformasi, pembungkusan lepuh dan pembungkusan kulit kerang. Ia juga serasi dengan proses pencetakan dan pelabelan, membolehkan penyesuaian dan penjenamaan pembungkusan.

SPESIFIKASI TEKNIKAL FILEM PVC TEGAR(BLISTER PACKAGING)

| tidak. | PARAMETER | KAEDAH UJIAN | UNIT | STANDARD |

|---|---|---|---|---|

| 01 | Warna / Rupa | Visual | — | Mengikut Spesimen Standard |

| 02 | Ketebalan filem PVC | DIN 53479 | Mikron | 60 HINGGA 100 ± 12%, 101 HINGGA 200 ± 10%, 201 HINGGA 400 ± 7%, 401 HINGGA 800 ± 5% |

| 03 | Ketumpatan | DIN 53479 | g/ cm 3 | 1.35 ± 0.02 |

| 04 | Kekuatan Tegangan | DIN EN ISO527 | Kg/cm2 (Min) | 450 |

| 05 | Kestabilan Dimensi MD | DIN 53377 | % (Maks) | 60 HINGGA 100 -12 maks, 101 HINGGA 200 – 10 maks,201 HINGGA 400 -7 maks,401 HINGGA 800 – 5 maks |

| 06 | Kestabilan Dimensi TD | DIN 53377 | 60 HINGGA 100 + 5 maks,101 HINGGA 200 + 3 maks,201 HINGGA 400 + 2 maks,401 HINGGA 800 + 1 maks | |

| 07 | Toleransi lebar | mm (Maks) | ± 1 | |

| 08 | Titik Pelembutan Vicat | ASTM –D 1525 | °C | 74 ± 2 |

| 09 | Pengenalan | FTIR | — | Untuk mematuhi |

Laporan Ujian

| item | Spesifikasi | Keputusan Ujian | Kesimpulan | ||

| Penampilan | Helaian PVC Sepatutnya Telus, seragam. Tidak membenarkan untuk mempunyai kedutan, kotoran berminyak, pemerah mata, tebuk, kekotoran. Diameter Fisheyesshhh1.3mm | Padankan Norma | Berkelayakan | ||

| Kenal pasti | Analisis spektrum inframerah | Harus seragam kepada spektrum antitesis | -- | -- | |

| Ketumpatan g/cm3 | 1.35~1.45 | 1.36 | Berkelayakan | ||

| Fizik | Wap Air Penularan g/m2·24j 23ºC, RH90% | ≤2.5 | 2.2 | Berkelayakan | |

| Penghantaran Oksigen cm3/m2·24j·0.1MPa | ≤30 | 20 | Berkelayakan | ||

| Kekuatan Tegangan MPa | MD:≥ 44 | 52.8 | Berkelayakan | ||

| TD:≥ 44 | 54.7 | Berkelayakan | |||

| Kesan Bola Jatuh Kadar Rapuh | TD: tidak lebih daripada 2 kerosakan | 0 | Berkelayakan | ||

| MD: tidak lebih daripada 2 kerosakan | 0 | Berkelayakan | |||

| Kadar Pengecutan Pemanasan % | -6~+6 | -3.2+1.4 | Berkelayakan | ||

| Kekuatan Pengedap Pemanasan N/15mm | ≥7.0 | 13.6 | Berkelayakan | ||

| Kandungan VCM mg/kg | ≤1 | 0.4 | Berkelayakan | ||

| Ujian Pengekstrakan | Darjah Jelas | Harus jelas | Jelas | Berkelayakan | |

| Ujian Pengoksidaan | Perbezaan Titer≤1.0 ml | 0.78 | Berkelayakan | ||

| Logam Berat mg/kg | ≤1 | <1 | Berkelayakan | ||

| Tidak Meruap | air mg | ≤30.0 | 10.3 | Berkelayakan | |

| 65% Etanolmg | ≤30.0 | 6.9 | Berkelayakan | ||

| Hexanemg | ≤30.0 | 2.8 | Berkelayakan | ||

| Barium | Harus jelas | Padankan Norma | Berkelayakan | ||

| Pengplastik | Kurang daripada 6% | 2% | Berkelayakan | ||

filem PVC tegar gred farmaseutikal jelas 0.2mm kami ialah pilihan yang boleh dipercayai dan serba boleh untuk keperluan pembungkusan farmaseutikal, menawarkan perlindungan dan keterlihatan untuk produk anda.

Dalam tempoh 15-20 hari selepas menerima pembayaran...more