50% kepingan keras PET kitar semula untuk pembentukkan termo

- top leader plastic

- China

- 15 hari bekerja

- 1500 tan/bulan

- maklumat

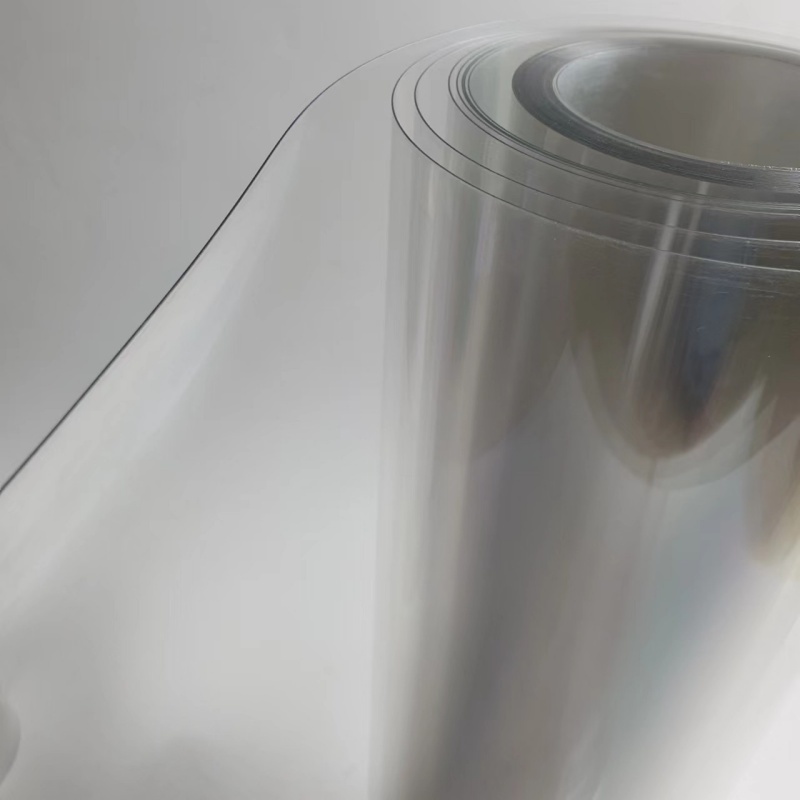

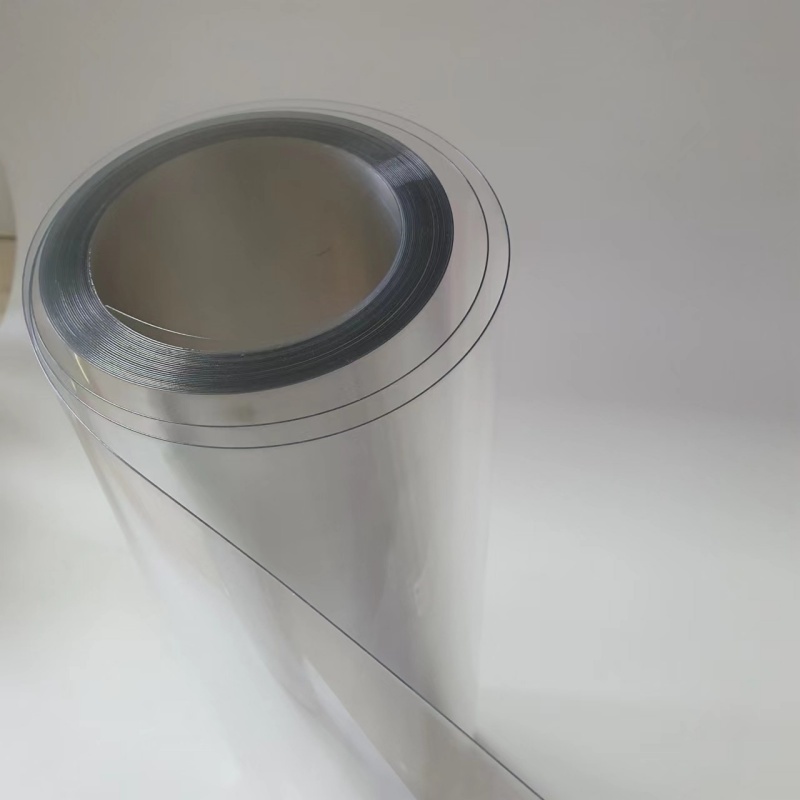

50% recycled PET hard sheet for thermoforming

Material characteristics

Environmental protection: Contains 50% recycled PET material, effectively reducing the use of virgin plastics, reducing pressure on the environment, in line with the concept of sustainable development, and helping to reduce the generation of plastic waste and dependence on petroleum resources.

Mechanical properties: Although it is a recycled material, it still has good strength and rigidity after reasonable processing and formula adjustment, and can meet the requirements of stretching, bending, etc. in the thermoforming process. The finished product can withstand certain pressure and impact and protect the items in the package.

Transparency: Maintaining a high degree of transparency, the products in the package can be clearly seen, which is convenient for display and sales. It has advantages in areas such as food and daily necessities that require high packaging display.

Chemical resistance: It has good stability to many chemical substances, can resist the erosion of acids, alkalis and solvents, is suitable for packaging various types of items, and will not affect product quality due to chemical reactions caused by contact with the contents.

Production process: Usually a multi-layer co-extrusion process is used to extrude recycled PET materials and other additives or virgin PET materials in layers to form a hard sheet with specific properties. During the production process, the raw materials need to be strictly screened and processed to ensure the quality and performance of recycled PET. At the same time, the extrusion temperature, pressure, speed and other parameters are precisely controlled to ensure the thickness uniformity, physical properties and appearance quality of the sheet.

Application areas

Food packaging: can be used to package fruits, vegetables, cakes, sushi and other foods at room temperature

Electronic product packaging: can be made into blister trays of various shapes for packaging mobile phones, computer accessories, electronic components, etc., to fix and protect the products and prevent them from being damaged by collision and friction during transportation and storage.

Daily necessities packaging: such as the packaging of daily necessities such as cosmetics, stationery, toys, etc., can enhance the appearance of the product and attract consumers to buy.

Dalam tempoh 15-20 hari selepas menerima pembayaran...more