Mendedahkan Ciri dan Aplikasinya dalam Pinggan Makan, Pembungkusan Lepuh, Dulang Anak Benih dan Helaian Antistatik

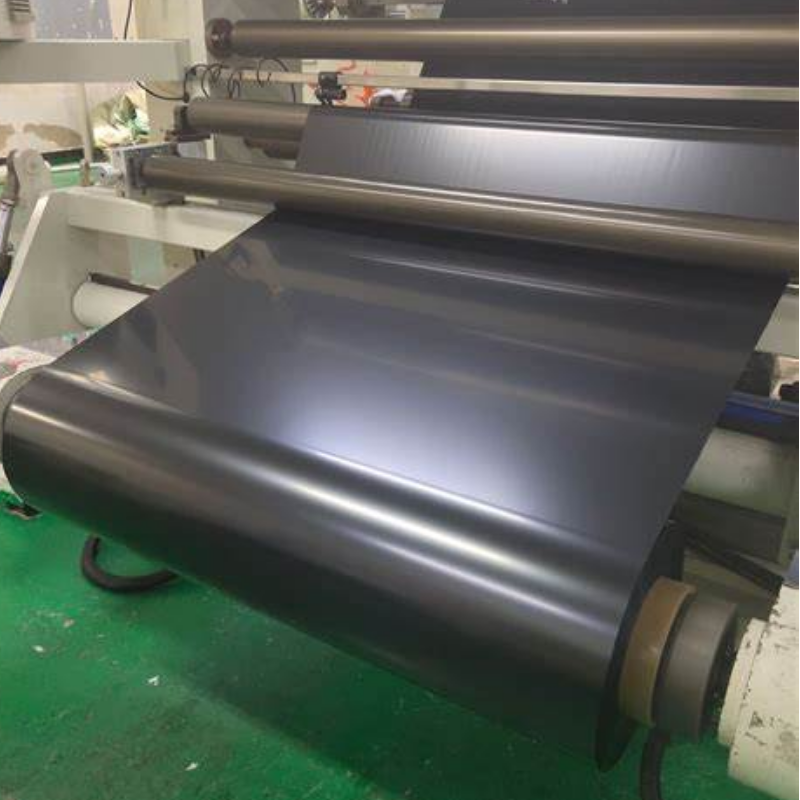

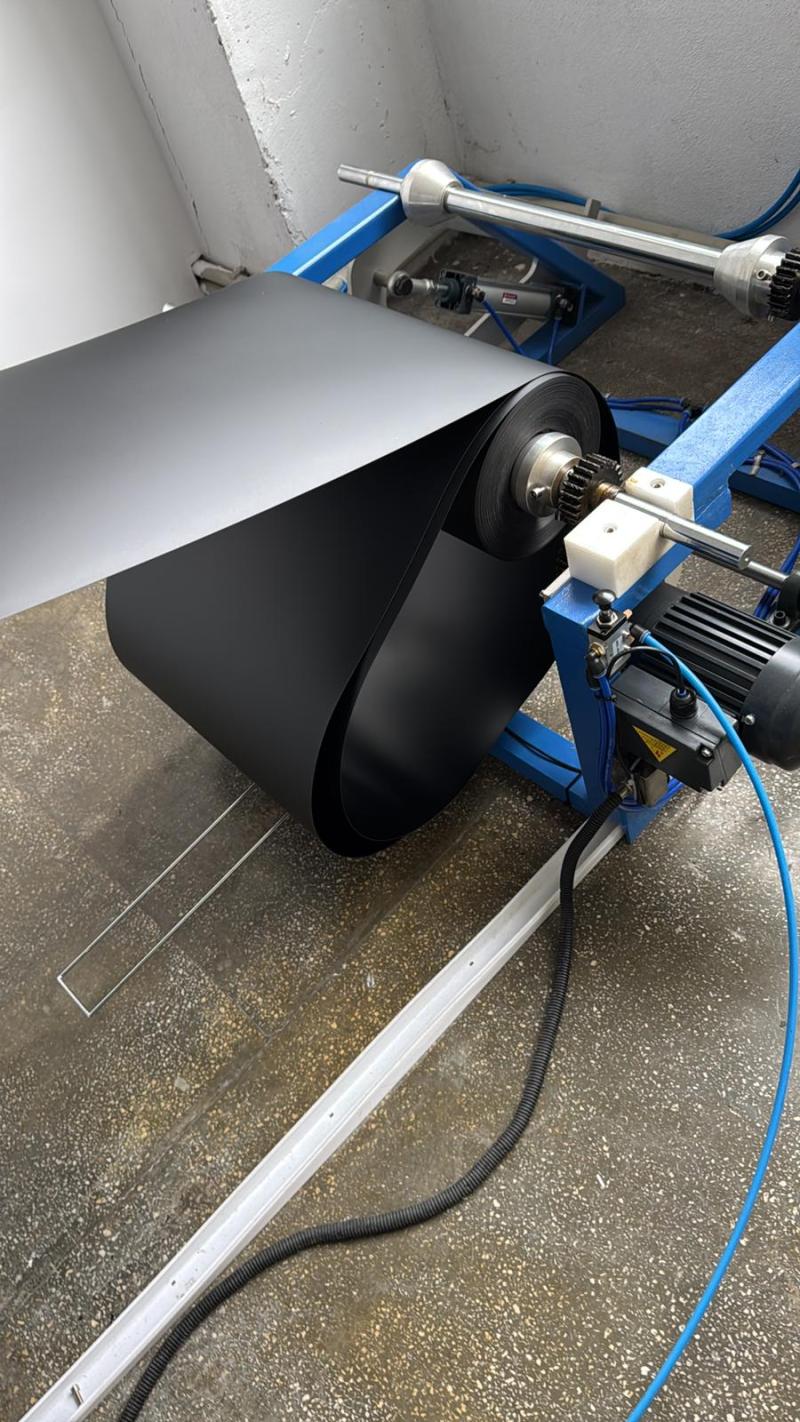

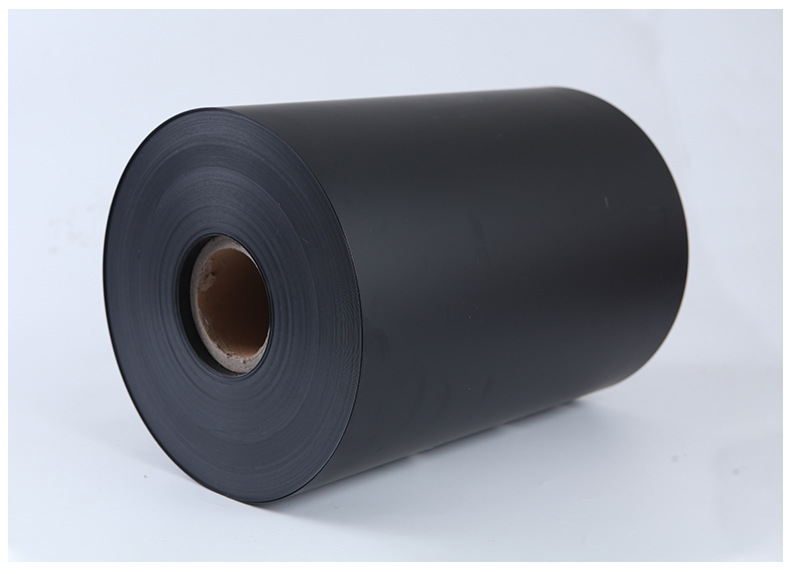

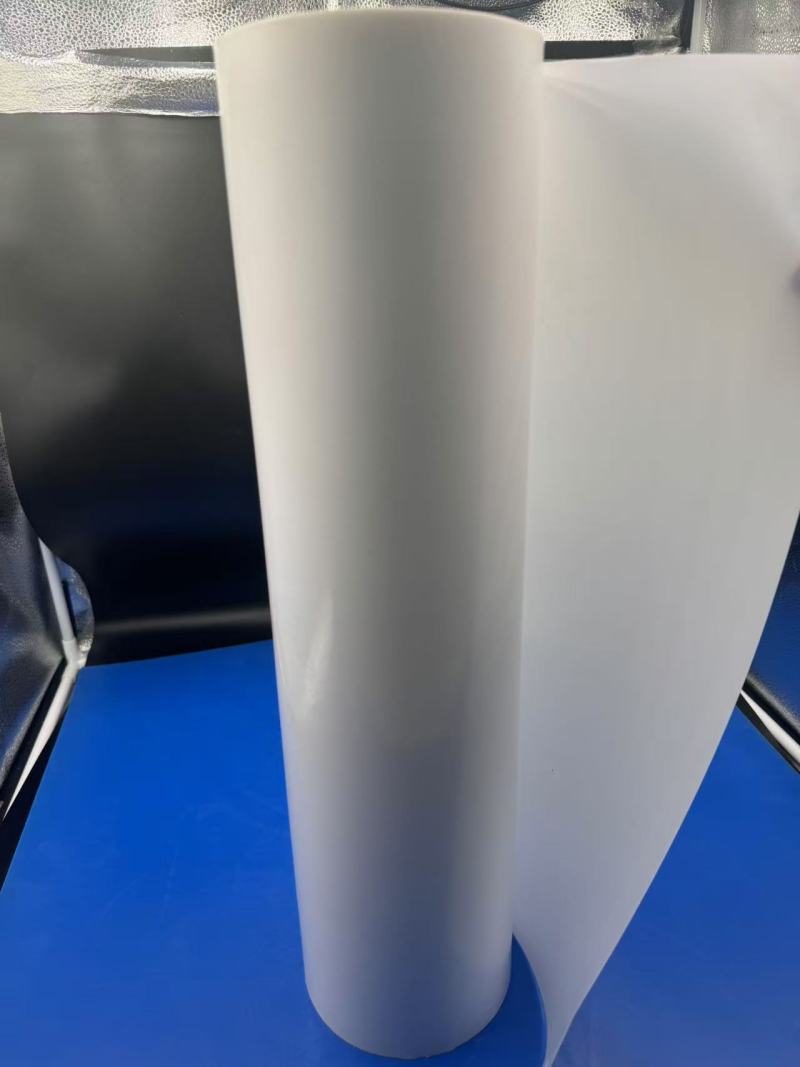

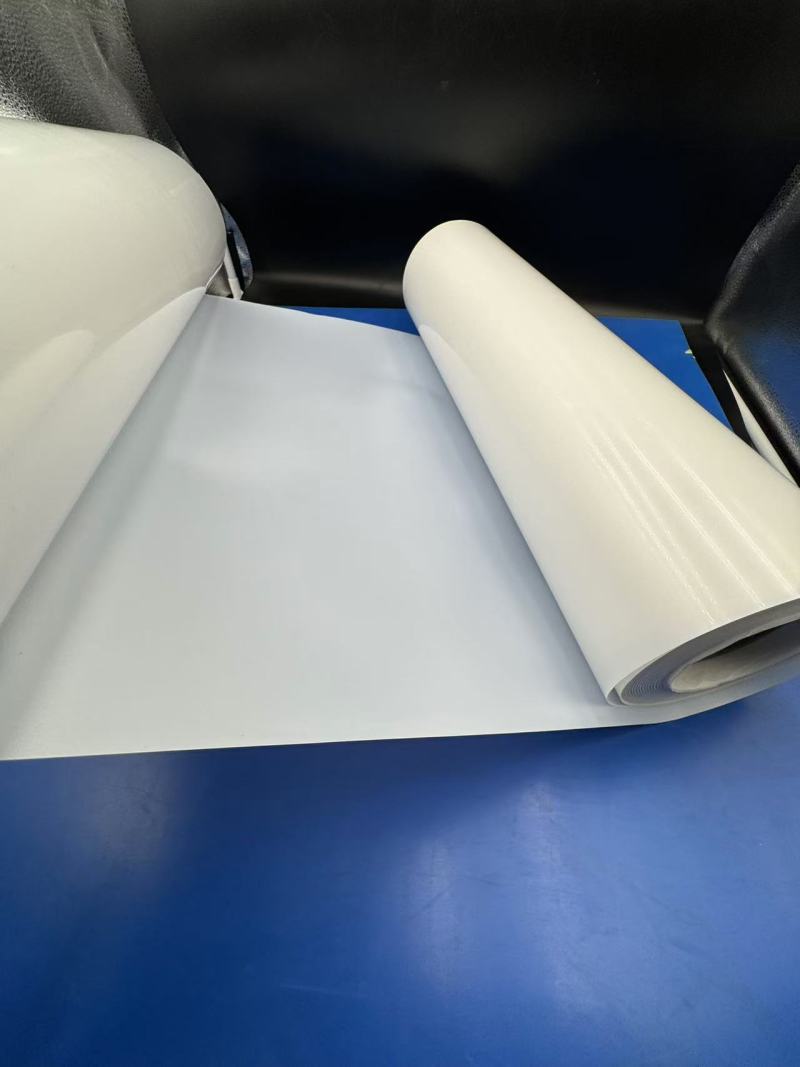

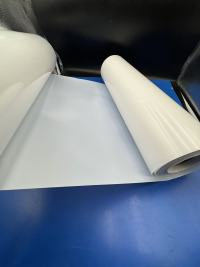

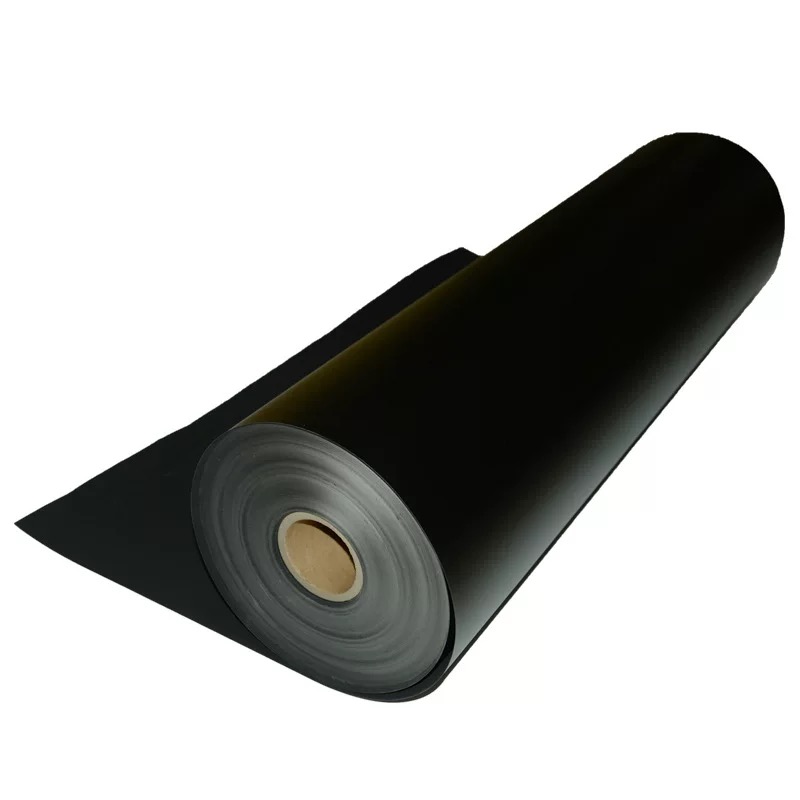

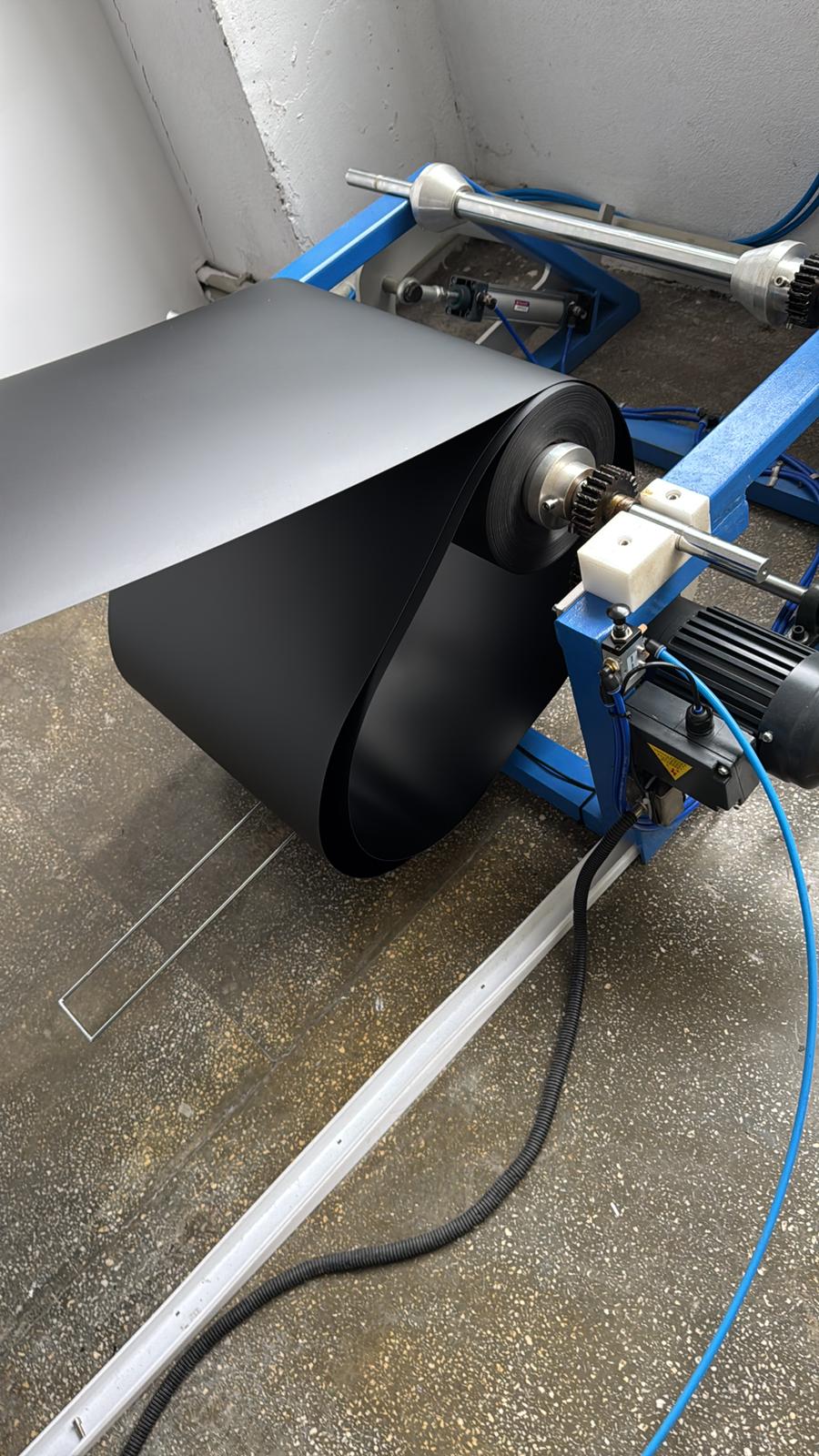

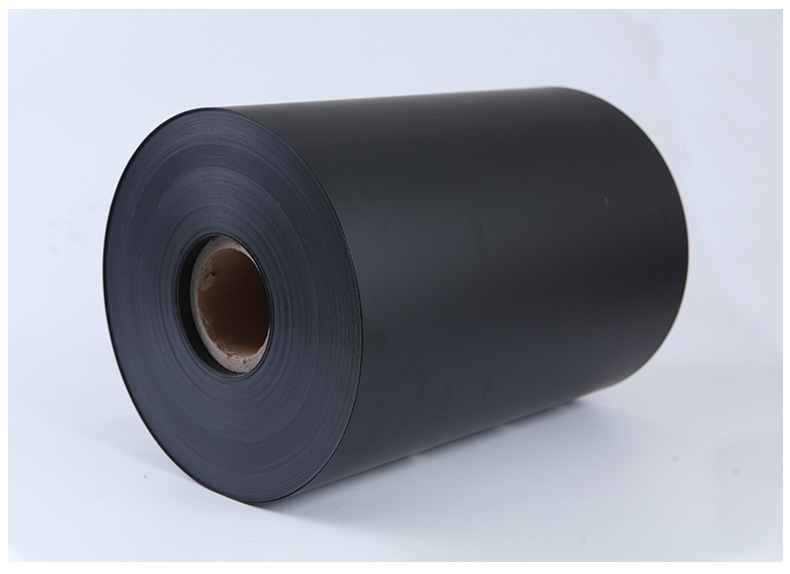

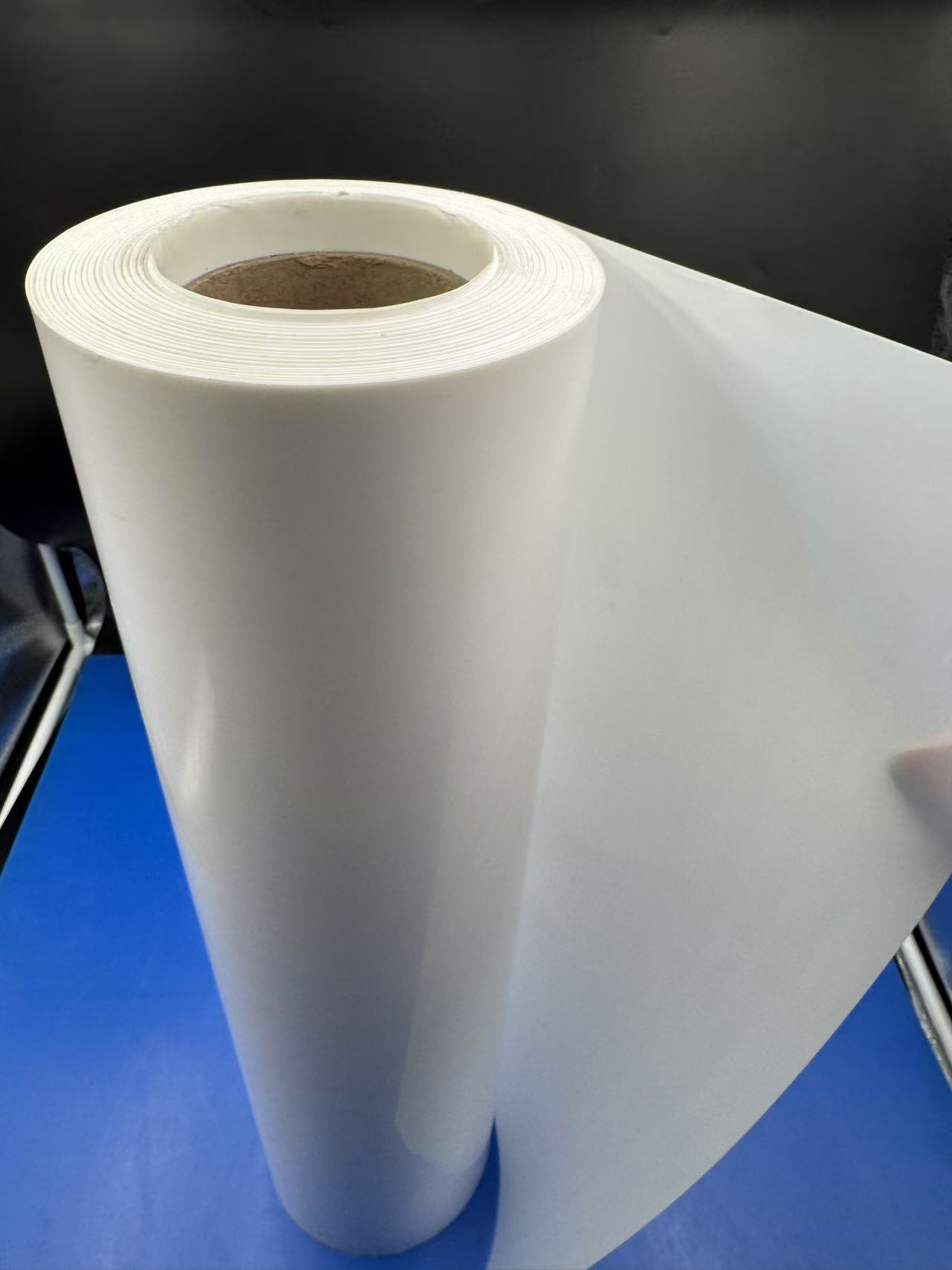

Bahan: PP Thermal formed sheet

Ketebalan 0.25-0.9mm/penyesuaian

Saiz: 300mm/Penyesuaian

GRED: Filem gred makanan

warna: hitam / putih / penyesuaian

lokasi: china

penggunaan: untuk dulang makanan, bekas makanan gelombang mikro

- TOPLEADER

- China

- 15HARI BEKERJA

- 5000T/M

- maklumat

- Video

- Download

Introduction

PS film is versatile and economical, hence finding its place in almost all industries due to a unique combination of properties. This article will discuss some of the characteristics of the PS film and its applications in tableware, blister packaging, seedling trays, and antistatic sheets, among others, to give an overview of how the material shapes our daily lives.

Characteristics of PS Film

Transparency and Gloss:

PS film is reputed for crystal clarity, hence ideal for applications where aesthetics are a major factor. Its high gloss and sparkle offer an aesthetic advantage in packaging, among other applications.

Strength and Durability:

PS film has high moisture vapor, oxygen, and CO2 transmission rates, useful in packaging fresh foods where respiration is required but also limit utility of the film in barrier applications.

Printability:

The surface of the film itself is typically printable. It provides good bright graphics and branding, hence being one of the favorites for packaging solutions where print aesthetics are relevant.

Antistatic Properties:

Treated or modified PS may exhibit antistatic properties that are very essential in the packaging and handling of electronic components, preventing static electricity damage.

Tableware Applications

In tableware applications, high clarity and good printability in PS film have been employed to make disposable cups, plates, and food containers. Low in cost and amenable to various shapes by thermoforming, the material is useful for:

Yogurt Cups and Food Trays: PS can present fresh food in clear packaging, which adds to its consumer appeal.

Disposable Cutlery and Containers: The strength in the film provides the structural integrity needed in these products to withstand normal use.

Blister Packaging

Blister packaging employs PS film because of its very good thermoforming capability, which provides tight, protective packaging for such consumer products as pharmaceuticals, electronics, and small hardware:

Pharmaceuticals: The clarity of PS enables the easy inspection of medication, while barrier properties, in modified forms, maintain product integrity.

Electronics: Antistatic variants of PS film find a very specific application in this industry by protecting sensitive components from static discharge.

Seedling Trays

In agriculture, PS films are made into seedling trays because of the following reasons:

Durability: These can withstand the rigors of handling and the variable conditions of nurseries.

Light Transmission: Since PS is translucent, light transmits through, promoting plant growth.

Reusability: Most seedling trays made from PS can be thoroughly cleaned and used again, so reusing instead of disposing saves resources.

Antistatic Sheets

PS usage in antistatic sheets plays a critical role in electronics production:

Electronic Packaging: PS films, modified with antistatic properties, safeguard against static electricity that would otherwise destroy electronic circuits.

Aplikasi Bilik Bersih: Di sini, rintangan permukaan bahan dioptimumkan untuk mengelakkan pengumpulan statik untuk memastikan keselamatan semasa pemasangan elektronik berlaku.

Pertimbangan Alam Sekitar

Walaupun PS menawarkan utiliti yang besar, ia tidak mampu mengabaikan isu alam sekitar. Penambahbaikan dalam:

Kitar Semula: Walaupun sukar, kitar semula PS menjadi semakin diamalkan apabila negara membangunkan infrastruktur pengurusan sisa moden.

Analog Terbiodegradasi: Turut dikaji ialah pembangunan biopolimer yang menghampiri sifat PS dengan kebolehdegradan yang dipertingkatkan.

Kesimpulan

Ciri-ciri filem PS menjadikannya sangat serba boleh untuk aplikasi, daripada barangan harian seperti pinggan mangkuk kepada kegunaan khusus seperti pembungkusan antistatik. Keupayaannya untuk dibentuk menjadi bentuk yang kompleks, bersama dengan kejelasan optik dan kekuatan mekanikalnya, terus menjadikan PS sebagai bahan pilihan. Bagaimanapun, dalam langkah ke bahan yang lebih mampan, industri dicabar untuk berinovasi sambil masih memanfaatkan sifat berfaedah PS.

Penerokaan pembuatan filem PS selanjutnya menunjukkan bukan sahaja kegunaannya tetapi juga keperluan berterusan untuk inovasi yang akan menjadikannya mesra alam, dengan tujuan bahan ini berterusan ke masa depan kita serta menjadi sebahagian daripada masa kini kita.

Dalam tempoh 15-20 hari selepas menerima pembayaran...more